Overview

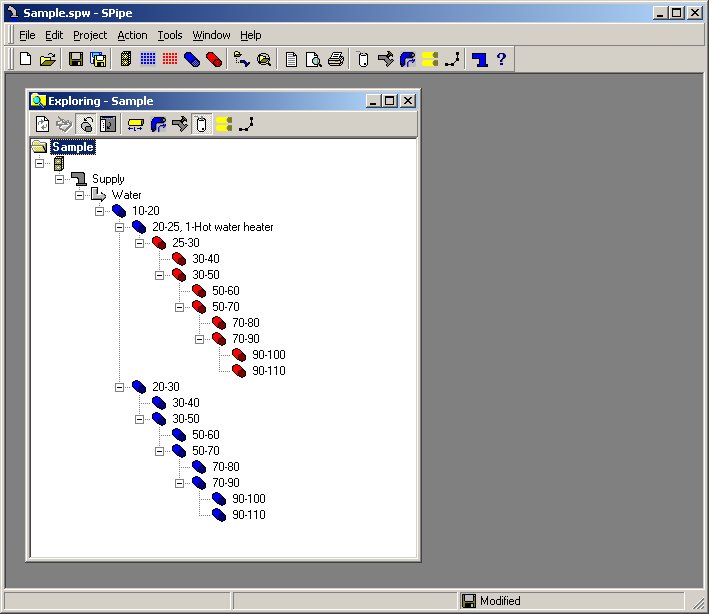

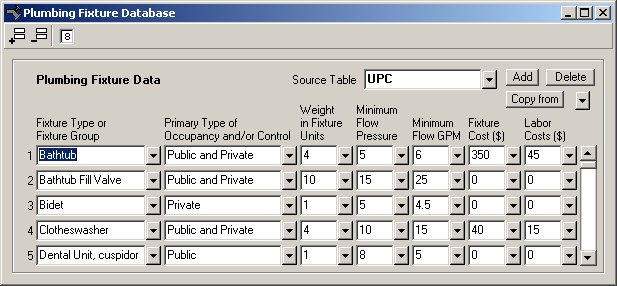

S-Pipe computes optimal pipe sizes for hot and cold water domestic water supply systems in both residential and commercial buildings. It can handle systems with virtually unlimited numbers of pipes. Besides computing pipe sizes, S-Pipe can also perform a system analysis complete with a bill of materials and labor estimate. Reports list the GPM water flow, velocity, and pressure losses through all pipe sections, the maximum system demand pressure, and the total water GPM demanded by the system. S-Pipe is very easy to use as it contains built-in data concerning fitting equivalent lengths, pipe materials, internal pipe diameters and C-Values, fixture unit quantities and pressure requirements, equipment flow and pressure requirements, materials and labor costs, and demand GPM curves. Any or all of the built-in data can be revised to meet your particular needs.

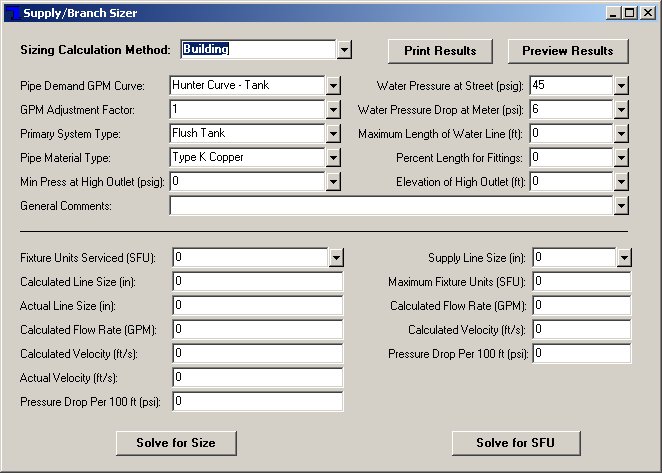

Program Input

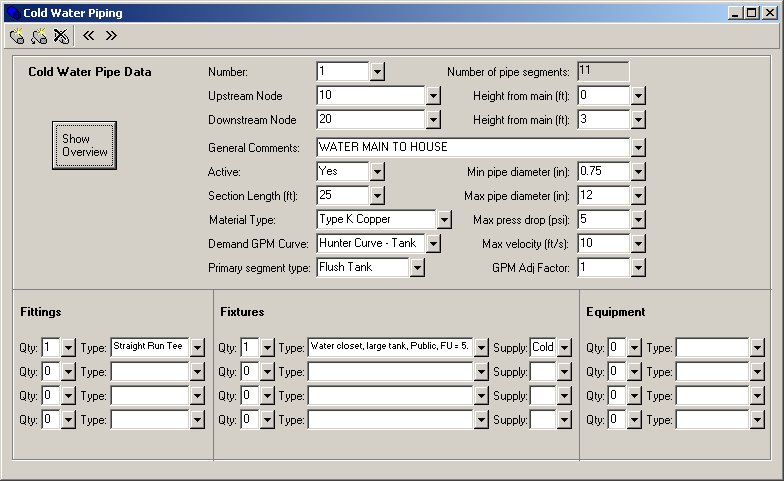

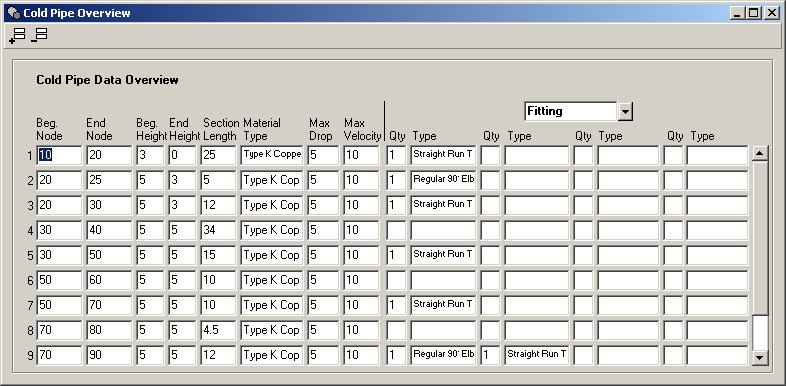

S-Pipe requires two types of data: general project data and pipe section data. The general project data includes the project name, the name of the designer, the client, the date, and other such information. The pipe data requires that each pipe section must be defined as having a beginning and ending node along with the pipe type and length. Numerous pipe material types are built in including copper, cast iron, PVC, and even PEX. Additional pipe materials are easy to add. In addition, the type and quantity of fittings and fixtures that exist on each pipe section must be specified. There is also provision for equipment and other special items such as dishwashers, water heaters, and backwater flow preventers. Optional pipe input data includes provision for specifying a maximum allowed pressure drop and a maximum allowed velocity. These constraints along with an allowable pipe size range may be changed from pipe to pipe. Once all the pipe sections have been entered, the water distribution system is ready for calculation.

Calculation Method

S-Pipe uses two criteria for sizing pipes, maximum allowed water velocity and maximum allowed pressure drop per 100 ft. of pipe length. If physical space problems exist you may also specify a limited range of sizes that S-Pipe can select from when calculating a size. You can even specify pipe sizes so that no size computation is performed. When S-Pipe is allowed to calculate sizes, it uses the Hazen-Williams equation to determine the pressure drop due to friction for a particular pipe size. Water velocity is calculated by first determining the expected gpm flow rate and then dividing by the pipe cross sectional area. Given no physical constraints, S-Pipe always selects the smallest pipe size such that neither the allowable maximum water velocity or the allowable maximum pressure drop is exceeded.

Program Output

S-Pipe provides both input and output reports. The input reports reflect all the data that you entered, while the output reports list all values calculated by the program. The reports list pipe data including fittings and fixtures selected, general project information, system design requirements, and a bill of materials with labor costs. S-Pipe allows you to specify exactly which reports you want and in what order you want them. Note that S-Pipe provides many intermediate values so the results are easy to check and verify by hand.